Showing 1–9 of 10 results

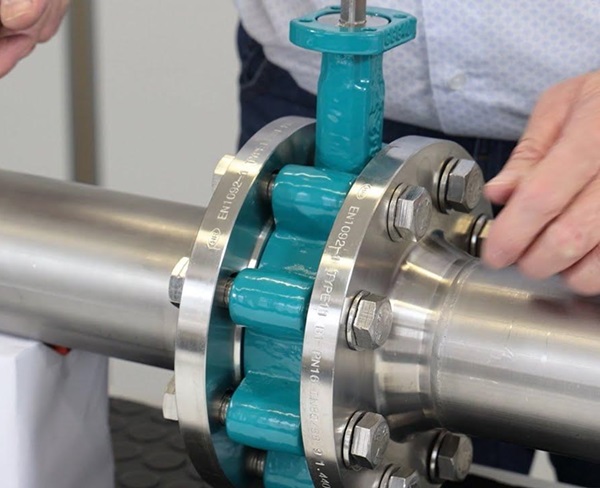

Butterfly valves bring you efficient, space-saving control for smooth flow regulation, ideal for a wide range of applications from HVAC systems to industrial pipelines. Their compact design offers quick, quarter-turn operation, letting you adjust flow with precision and ease. Built for durability, butterfly valves handle high-pressure and high-temperature conditions, making them a dependable choice for both commercial and residential systems. With easy installation and reliable performance, butterfly valves keep your systems running smoothly while saving you time and space.

Filter by Materials

- Al-Bronze (1)

- Carbon Steel (5)

- Cast Iron + Epoxy (4)

- CF8 (2)

- CF8M (2)

- Ductile iron + Epoxy (2)

- PVC-U (1)

- Stainless Steel (7)

- WCB (1)

Filter by Diameter

- DN100 - 4" inch (5)

- DN125 - 5" inch (5)

- DN150 - 6" inch (5)

- DN200 - 8" inch (5)

- DN25 - DN1000 (1)

- DN250 - 10" inch (4)

- DN300 - 12" inch (5)

- DN350 - 14" inch (5)

- DN400 - 16" inch (5)

- DN50 - 2" inch (5)

- DN50 - DN1200 (1)

- DN50 - DN2000 (2)

- DN500 – 20" inch (1)

- DN600 – 24" inch (1)

- DN65 - 2 1/2" inch (5)

- DN80 - 3" inch (5)

- DN80 - DN2400 (1)

Filter by

- Butt Welding (2)

- Double Flanged (1)

- Flange (1)

- Lug Type (4)

- Wafer Type (4)

Types of Butterfly Valves

Whether you’re looking for lightweight wafer butterfly valves, lug style butterfly valves, triple offset butterfly valves or the whole new of flanged butterfly valves, stay here for a while and we’ll show you a quick overview of some common types of butterfly valves.

Wafer Butterfly Valve

This type of valve is thin and designed to fit between two flanges. It’s commonly used for low-pressure systems to prevent backflow in pipes. Wafer butterfly valves are usually held in place by bolts that run through the valve body and surrounding flange.

Triple Offset Butterfly Valve

This valve has three offsets, providing a tighter seal and reducing wear on the sealing surfaces. It’s ideal for high-pressure, high-temperature, or high-risk applications, such as in industries where leaks could be hazardous.

Lug Style Butterfly Valve

The lug style butterfly valve has threaded inserts, or “lugs,” which allow it to be bolted to the pipe flanges without nuts. This design makes it easier to disconnect one side of the pipeline without disturbing the other. It’s typically suitable for moderate-pressure systems.

Flanged Butterfly Valve

Flanged butterfly valves have flanges on each end, allowing them to be bolted directly to the pipe flanges, making them ideal for high-pressure systems. They offer a reliable, easy-to-maintain connection and are often used in water treatment, chemical processing, and HVAC systems.

butterfly valve vs gate valve

A butterfly valve and a gate valve serve different purposes in controlling fluid flow. Butterfly valves are generally quicker to operate and more compact, making them ideal for applications that require fast on/off control and flow regulation in larger pipe systems. Their design allows for a smooth, lightweight mechanism with relatively low cost, but they might not provide as tight a seal as gate valves, especially in high-pressure systems. On the other hand, gate valves are designed for fully opening or closing the flow, offering a better seal and minimal flow resistance when fully open. They are slower to operate and bulkier, making them more suited for applications where a tight shutoff is needed, but they are less effective for throttling or regulating flow.

In essence, butterfly valves are preferred in systems where space, weight, and fast operation are critical, while gate valves excel in providing a secure, tight seal for on/off applications, especially in systems that handle high-pressure fluids or require minimal leakage.

FAQs for Butterfly Valves

Butterfly valves are commonly used to control the flow of fluids in a wide range of applications, including water supply, wastewater treatment, chemical services, HVAC, and food processing. They are especially useful in systems that require quick shut-off or throttling and are often used in larger pipe diameters where space and weight are critical factors.

The main advantage of a butterfly valve is its compact and lightweight design, which allows for easy installation in tight spaces and quick, 90-degree operation. This design makes it cost-effective and energy-efficient, especially in larger diameter pipes.

The primary disadvantages of butterfly valves are that they may not provide a perfect seal in high-pressure applications and can experience wear on the sealing surfaces over time. Additionally, the disk remains in the flow path even when open, which can cause some flow restriction and turbulence.

The three main types of butterfly valves are wafer, lug, and triple offset. Wafer butterfly valves are simple, compact, and designed to fit between flanges. Lug butterfly valves have threaded inserts for more secure installation. Triple offset butterfly valves have an advanced sealing mechanism that provides a tighter shut-off for high-pressure and high-temperature applications.