When dealing with fluid control systems, one common question arises: what type of valve should you choose? Among various options, ball valves stand out for their reliability and efficiency. Have you wondered how ball valves function?

This guide will help you understand everything about ball valve—from their definition and working principles to their types, functions, applications, and how to select the right one for your needs. With this knowledge, you’ll be better equipped to make informed decisions regarding ball valves in your projects.

What is a Ball Valve?

A ball valve is a crucial component in various piping systems, designed to control the flow of liquids and gases through the use of a pivoting ball that has a port through its center. This quarter-turn valve utilizes a hollow, perforated ball that pivots within the valve body to either permit or block flow.

The ball bore can be designed with perforated plates or multiple small bores to enhance pressure drop and reduce noise levels, thereby improving the valve’s performance and efficiency in various applications.

When the ball’s hole aligns with the fluid’s direction, flow is allowed through the pipe; when it is turned 90 degrees, the water flow is halted. This simple yet effective mechanism makes ball valves popular in many industries.

Advantages and disadvantages of ball valve

| Feature | Advantages | Disadvantages |

|---|---|---|

| Durability | Constructed from robust materials, suitable for high-pressure, high-temperatures and low-temperature applications in hydraulic systems. Long operational lifespan. | This type ball valve can be more expensive than simpler valve types. |

| Reliable Sealing | Excellent sealing capabilities, reducing the risk of leaks even after prolonged use. | Sensitive to debris, which can affect operation. |

| Quick Operation | Quarter-turn mechanism allows for rapid opening and closing, useful in emergencies. | Rapid operation can lead to water hammer issues. |

| Versatility | Suitable for both on/off control and throttling applications with various fluids. | Limited precision in flow regulation compared to other valve types. |

| Low Torque Requirements | Requires less torque to operate, making it easier to use, especially in automated systems. | Maintenance can be challenging, especially for one-piece designs. |

| Minimal Flow Resistance | Full-bore designs offer minimal flow resistance, promoting efficient fluid transfer and reducing extra friction losses in hydraulic systems. The valve opening size impacts the flow of different fluids, contributing to achieving minimal pressure drops. | Some materials may have temperature limitations, restricting use in extreme conditions. |

How Does a Ball Valve Work?

The ball valve operates on a simple principle: a ball with a hole in it rotates within the valve body. When the ball valve handle is turned, the ball’s hole aligns with the inlet and outlet ports, allowing free flow of fluid. In the closed position, when the ball is turned 90 degrees, the hole becomes perpendicular to the flow, effectively stopping it. This mechanism ensures that the ports maintain the same diameter as the pipe, allowing for quick operation and minimal turbulence.

Ball valves are widely used for control of fluid flow and pressures in various systems. By minimizing obstructions, they also help reduce friction losses, making them ideal for various applications where efficient flow management is crucial.

Function of Ball Valves

| Function | Description |

|---|---|

| On/Off Control | Provides quick and reliable on/off control of fluid flow. The valve is open when the ball aligns with the flow path; closed when turned 90 degrees. |

| Minimal Flow Resistance | Full-port ball valves maintain the same diameter as the pipe, allowing for minimal flow resistance and reduced friction losses. |

| Sealing Capability | Offers excellent sealing capabilities, minimizing the risk of leaks even after prolonged use. |

| Versatility | Capable of handling a wide range of fluids, including water, oils, gases, and corrosive substances, depending on the material and design. |

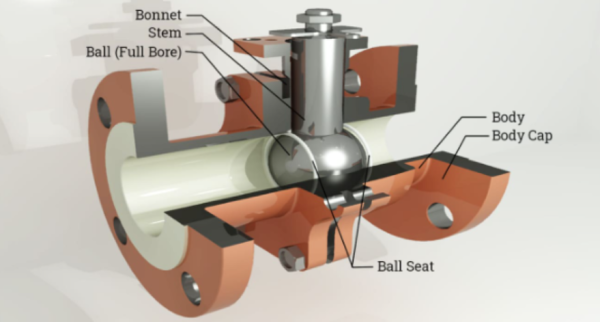

What are the Components of a Ball Valve?

A standard ball valve is usually composed of valve housing, ball, valve seat, shaft, bonnet andelectric Actuator. In order to clearly illustrate the working principle and internal structure of the ball valve, please look at this cross-section, which shows the layout and structure of the various components inside the valve.

- Valve Housing: The valve housing is the main structure that houses all internal components of standard ball valves. It provides the framework for the valve and connects it to the piping system, ensuring a secure and stable installation. The design of the valve housing is crucial as it supports the entire valve and protects the internal parts from environmental factors, such as corrosion and contaminants.

- Ball:A spherical element with a central hole (or bore) that controls the flow. When the hole is aligned with the flow direction, fluid can pass; when turned 90 degrees, the flow is blocked. As the core of the valve, the ball is typically made of durable materials such as stainless steel, brass, carbon steel, or PVC, depending on the industrial applications.

- O Rings and Seats: The seats provides a tight seal around the ball, ensuring no liquid or gas escapes when the valve is closed.

- Shaft: his connects the ball to the actuator and transmits the rotational movement necessary to open or close the valve.

- Bonnet: This part seals the valve and contains the packing, which helps prevent leaks.

- Electric Actuator: In some configurations, an electric actuator automates the opening and closing of the valve.

All Types of Ball Valves

Most ball valves are essential components in various fluid control applications, and they come in different types based on size, materials, pressure ratings, actuation methods, construction, ball valve design, and connections. Here’s an overview of the different types of ball valves available:

By Size

Ball valves are available in different sizes to suit various piping systems. The common unit of measurement for valve sizes is inches (in) or millimeters (mm). Here are some typical sizes of them.

| Size (inches) | Size (mm) | Common Applications |

|---|---|---|

| 1/4″ | 6 mm | Small plumbing and low-flow systems |

| 1/2″ | 15 mm | Residential water supply and heating |

| 3/4″ | 20 mm | Irrigation and HVAC systems |

| 1″ | 25 mm | Industrial water lines and processes |

| 1.5″ | 40 mm | Fire protection systems |

| 2″ | 50 mm | Commercial plumbing and drainage |

| 3″ | 80 mm | Larger industrial applications |

| 4″ | 100 mm | Heavy-duty industrial systems |

By Materials

- Carbon Steel: Carbon steel ball valves are known for their high strength and durability, making them ideal for demanding applications such as oil and gas, chemical processing, and power generation. These valves can withstand high pressures and temperatures, providing reliable performance in harsh conditions.

- Stainless Steel: Stainless steel ball valves offer excellent corrosion resistance, making them suitable for applications involving exposure to harsh chemicals or high temperatures. Commonly used in food processing, pharmaceutical, and chemical processing industries, stainless steel valves ensure long-lasting performance and safety.

- Brass: Brass ball valves are highly resistant to corrosion and are often used in applications where exposure to seawater or other corrosive substances is a concern. They are commonly found in marine, oil and gas, and chemical processing applications, providing reliable and durable service.

- PVC: PVC ball valves are lightweight and highly resistant to corrosion, making them ideal for water treatment, chemical processing, and food processing applications. These valves are suitable for both low and high-temperature environments, offering versatility and ease of installation.

It’s important to note that the material used for the valve body and the ball can vary, depending on the specific application and the desired level of corrosion resistance. Selecting the right material ensures optimal performance and longevity of the ball valve in its intended environment.

By MaterialsPVC Ball Valve

Lightweight and resistant to corrosion, suitable for water and chemical applications.

Brass Ball Valve

Durable and often used in plumbing and heating applications.

Stainless Steel Ball Valve

Offers excellent corrosion resistance and is ideal for high-pressure and high-temperature applications.

By Operating Conditions

When selecting the appropriate type of ball valve, it’s essential to consider specific operating conditions and fluid characteristics to ensure safe and efficient system performance. Key factors include temperature, pressure, and the nature of the fluid. Ball valves can be designed for a range of conditions, such as high temperature, high pressure, low temperature, and low pressure. Here’s a brief overview of each type:

High Pressure Ball Valves

| Characteristics: | High pressure ball valves are designed for high-temperature fluids, typically made from materials like stainless steel or specialty alloys that can withstand elevated temperatures. |

| Applications: | Used in chemical processing, oil refining, and steam systems where high temperatures are prevalent. |

High Pressure Ball Valves

| Characteristics: | Capable of withstanding high-pressure environments, often featuring thicker valve bodies and stronger sealing materials. |

| Applications: | Commonly found in the oil and gas industry, hydraulic systems, and high-pressure water treatment applications. |

By Actuation

Manually operated ball valves

Operated by hand, suitable for applications where frequent adjustments are not necessary.

Electric Ball Valve

Allows for remote operation and automation, ideal for systems requiring precise control.

Pneumatic Ball Valves

Operated by compressed air, suitable for quick opening and closing in automated systems.

By Construction

- One-Piece Ball Valves: Made from a single piece of material, providing strength and reliability.

- Two-Piece Ball Valves: Composed of two separate pieces, allowing for easier maintenance.

- Three-Piece Ball Valves: Feature three separate pieces, providing flexibility for maintenance and repair.

By operating principles

Here’s a comparison table summarizing the different types of ball valves:

| TypeS | Construction | Advantages | Applications |

|---|---|---|---|

| Trunnion Ball Valves | Ball supported by trunnions for stability | High pressure and impact resistance, reduced wear | Oil, gas, and chemical industries |

| Floating Ball Valves | Ball floats between seats, sealed by fluid pressure | Excellent sealing capability, suitable for small diameters | Water treatment, plumbing, and general industrial use |

| Shut-Off Ball Valves | Designed to completely stop fluid flow | Reliable fluid isolation with excellent sealing | Fire protection systems and emergency shut-offs |

| Side Entry Ball Valves | Ball installed from the side, compact design | Easy to install and maintain, ideal for limited spaces | Oil and gas pipelines, municipal water treatment, HVAC |

| Plug Valves | Cylindrical or conical plug for fluid shutoff | Low-torque, quarter-turn operation, positive shutoff, compact design | Various applications including chemical processing, water treatment, and HVAC |

By Design

Another design aspect of a ball valve is their port profile. The hole through the ball can have different profiles such as V-shaped, reduced port (reduced bore) or full port: V-Shaped. A V-shaped or characterized profile allows for more precise control of flow rate by rotating the ball.

- Standard Port Ball Valve: Offers a standard flow path.

- Reduced Port Ball Valve: Features a smaller opening, which can lead to reduced flow rates.

- Full Port Ball Valve: Maintains the same diameter as the pipe, allowing for maximum flow.

- Three-Way Ball Valve: Allows for flow in multiple directions.

- Angle Ball Valve: Designed for specific flow directions, often used in tight spaces.

By Connection

- Standard (Threaded): Commonly used for easy installation.

- Flanged: Provides a secure connection for larger pipes.

Application of Ball Valves

Hydraulic Ball Valves

Specifically designed for hydraulic systems, these valves ensure efficient fluid control under high pressure. They are built to withstand the demanding conditions of hydraulic applications, providing reliable on/off control and flow regulation.

Water Ball Valves

Commonly used in water supply and plumbing applications, these valves provide reliable isolation and flow control. They are available in various materials to suit different water qualities and are ideal for both residential and commercial water systems.

| Other Applications |

|---|

| Chemical Ball Valves |

| Gas Ball Valves |

| Food and Beverage Ball Valves |

| Fire Protection Ball Valves |

| HVAC Ball Valves |

How to Select the Right Ball Valve

After understanding the basic of the ball valve, are you still have no idea to choose the proper ones for your projects? Here are some facts should be considered through the process! Let’s break it down into simple steps to make it easier for you, if you have any questions, please be free to consult with Ambers’ professional team.

- Application Type

Start by thinking about what type of fluid will be involved. Is it water, oil, or maybe a chemical? For example, if you’re dealing with water, a standard PVC ball valve might be just fine. For chemicals, a valve made of PTFE or a corrosion-resistant alloy will keep everything safe.

- Pressure and Temperature Ratings

Check the pressure and temperature ratings of the valve. Ensuring that the valve can handle the conditions in your system is essential. For instance, If you’re working with steam, a high-pressure stainless steel ball valve is necessary to withstand those high temperatures.

- Material Compatibility

Consider the valve material that can resist corrosion and wear from the fluid. Brass valves work great for potable water, while stainless steel or other metal options, as well as plastic,is a better fit for more aggressive chemicals.

- Size and Connection Type

Make sure the valve size matches your piping specifications. This includes checking the diameter and the type of connection you need. For example: If you have a 2-inch pipe, look for a 2-inch ball valve. If your piping has flanged connections, choose a valve that matches that type for easier installation.

- Actuation Method

Think about how you want to operate the valve. Do you need it to be manual, or would an automated option be preferable? If frequent adjustments are necessary, an electric or pneumatic actuated ball valve might be the way to go. For simpler setups, a manually operated valve could work just fine.

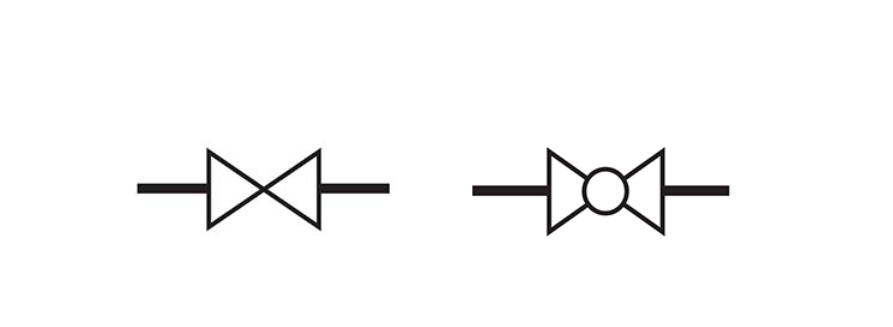

What are Ball Valve Symbols?

In engineering schematics, ball valve is typically represented by a circle with a line through it, indicating the ball’s position and flow direction.

Frequently Asked Questions

Q1. Gate Valve Vs. Ball Valve

Gate valves are used primarily for on-off control, while ball valves also provide excellent flow regulation. Ball valves are generally preferred for quick shut-off applications due to their efficient design. Here is a diagram to tell you the difference between gate valve and ball valve. If you are wonder ball valve vs check valve, please check this guide.

Q2. How to install a ball valve with a drain?

To install a ball valve with a drain, you’ll need a ball valve with a drain, pipe wrenches, Teflon tape, safety goggles, and a bucket to catch any residual water. Here are installation steps:

- Turn Off Water Supply: Shut off the water and drain the system by opening faucets.

- Cut the Pipe: Use a pipe cutter to remove the old valve if needed.

- Prepare Threads: Clean the pipe threads and apply Teflon tape for a watertight seal.

- Install the Ball Valve: Align the valve in the flow direction, tighten connections with wrenches.

- Attach the Drain: Connect a fitting or hose to the drain port, ensuring a tight seal.

- Turn On Water: Gradually restore the water supply, checking for leaks.

- Test the Drain: Open the drain valve to confirm proper function.

Q3. What does ball valve shut off mean?

A ball valve shut off refers to the function of a ball valve that allows for the complete stopping of fluid flow in a piping system. When the valve handle is turned 90 degrees, the ball inside the valve rotates to block the flow path, effectively shutting off the water or other fluids. This design makes ball valves ideal for applications requiring quick and reliable shut-off capabilities. They’re commonly used in plumbing, irrigation, and industrial applications due to their durability and ease of operation.

Q4. Materials Used in Ball Valve Construction

Ball valves can be made from a variety of materials, each chosen based on the specific application and the required level of corrosion resistance. The selection of materials plays a crucial role in the valve’s performance, durability, and suitability for different environments.

Conclusion

In summary, ball valve is essential components in fluid control systems, offering reliability, durability, and ease of use. Understanding their types, components, and applications will help you make informed decisions for your specific needs. Whether you’re looking for a simple shut-off solution or a more complex control valve, ball valves provide an effective and versatile option.

For more information or specific product inquiries, feel free to reach out to industry experts who can guide you in selecting the right ball valve for your application. For a wide range of high-quality ball valves, explore the products and services offered by Amber Industrial Valves.